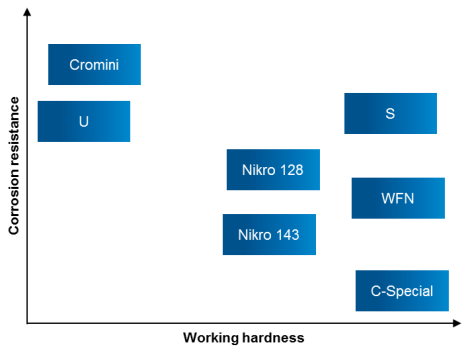

Ferro-Titanit grades

The tailor-made Ferro-Titanit alloys allow adaptation to the respective tribological system. This results in seven different grades for the Ferro-Titanit® MMCs, opening up areas of application ranging from metal processing and plastic granulation to applications in general mechanical engineering. These can be divided into three groups depending on the binder phase:

- Carbon martensite: In the soft annealed state, these grades are machinable and then martensitically hardened and tempered. Hardness up to 70 HRC are achieved.

- Soft martensite: The almost carbon-free soft martensite is characterized by increased nickel contents and is therefore often referred to as nickel martensite. Processing is carried out here in solution annealed condition. The working hardness is then adjusted by precipitation hardening in the temperature range around 480°C during ageing. The advantage of this alloying system is the very high dimensional stability during ageing.

- Austenites: In addition to their high wear resistance, austenitic grades also offer very high corrosion resistance. In this group there is an additional Nickel-based Ferro-Titanit® MMC in addition to the Fe-based grade, which offers a high corrosion and wear-resistance up to 800°C.