Nikrodur

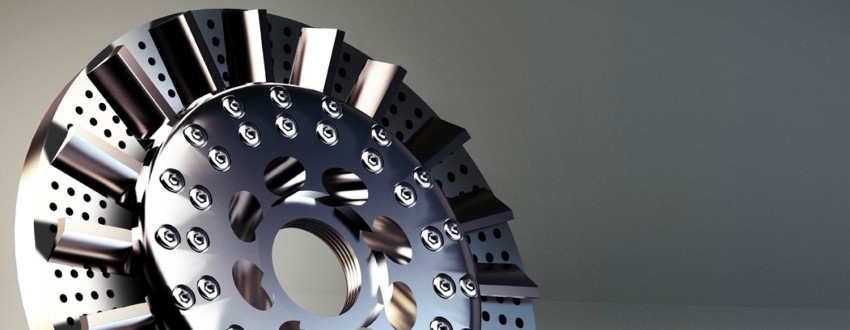

In the field of plastics production, today's trend is towards microgranules with a particle size of only approx. 0.5 mm. The microgranulate melts significantly faster than the standard granulate, which significantly shortens the cycle times for injection molding. At the same time, the existing drill holes of the die plates are correspondingly smaller at a maximum of 0.2 mm and more susceptible to so-called freezing. To prevent freezing, Nikrodur was specially developed for use as a perforated plate material. Nikrodur is characterized by a 50% higher wear resistance, a 30% higher corrosion resistance and a 20% lower thermal conductivity compared to the conventional perforated plate material ferro-titanite Nikro 128. This means that Nikrodur can significantly increase the service life and productivity of perforated plates.